By: Tex Enoch, Induron Water Tank Manager

Throughout 2021, Induron had the opportunity to work with several different contractors to specify coatings systems for the restoration and repainting of potable water storage tanks of various sizes operated by AQUA America.

Throughout 2021, Induron had the opportunity to work with several different contractors to specify coatings systems for the restoration and repainting of potable water storage tanks of various sizes operated by AQUA America.

The tanks

The size of the tanks varied widely (from 5000 to as much as 25,000 square feet). Like most water tanks, the exterior surfaces of these tanks were exposed to atmospheric conditions, including condensation, freeze-thaw cycles and UV weathering. The state of the tank’s carbon steel exteriors fluctuated from isolated areas of minor surface corrosion to large swathes of severe corrosion and pitting.

Project processes, materials and equipment

The spray equipment for these individual projects ranged from single-leg airless spray units to plural airless units. Some of the individual jobs required the use of dehumidification and heating equipment due to atmospheric conditions at the time of application. The proximity to nearby residential or commercial properties necessitated the use of spray and blast containment for many of the projects.

Project challenges and safety considerations

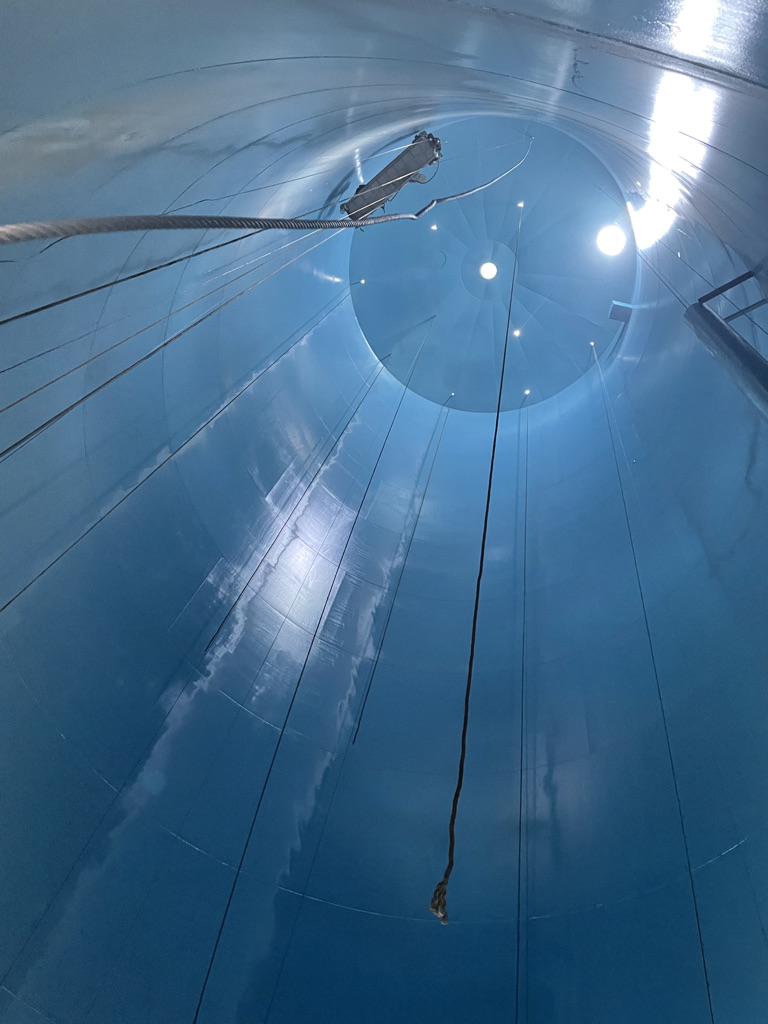

Environmental controls, including forced heating and dehumidification, needed to be introduced in order to facilitate both application and cure of the coating systems involved as well as flash-rust management of the blasted surface. This always presents a unique challenge as all these parameters must be custom adjusted for environmental conditions and for a given tank size and shape. All surface preparation and coating procedures involved specialized rigging.

The coating system

Induron provided a coatings system for both the interior and exterior of each water storage tank. All interior systems utilized CeramaPrime epoxy primer as a first coat top-coated with PermaClean 100.

CeramaPrime is a eramic-filled, highly-durable, immersion-capable epoxy primer that boasts a 45-minute time-to-recoat, a one-year maximum recoat window and low moisture vapor permeability. This product expands on our existing ceramic epoxy technology by offering a primer that increases efficiency, worker safety and long-term performance.

PermaClean 100 is a fast-curing, thick film, 100% solids epoxy tank lining for potable water applications with a proven track record. It provides enhanced edge retention, which improves corrosion protection on corners and sharp angles. It offers unparalleled film build, ultra-low permeability, absolute minimal undercutting and a non-ablative surface. The ability to apply PermaClean 100 at a very high dry film thickness enabled these jobs to be completed in one fewer coat, which decreased labor costs without compromising on in-service performance.

The outstanding contractor base and engineers involved in these projects has resulted in almost 10 years of outstanding protection of for Aqua America’s most valuable assets!