By: Russell Hicks, Induron Sales Representative

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

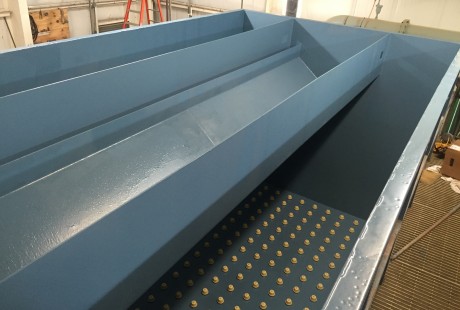

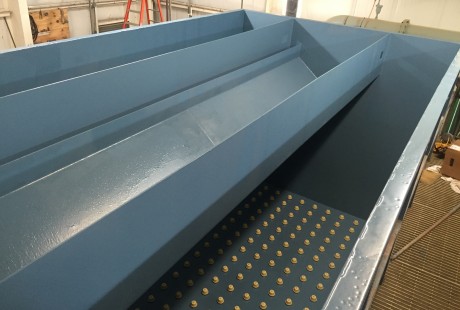

Sardis Water had two major problems. First, a new and larger clarifier needed to be built so that the two existing clarifiers could be converted into finish filters. Second, the water system needed a coating solution that could meet several demands. Sardis Water Authority needed the filter back in service quickly due to water usage demands. Additionally, the Sardis Water’s new coating system needed to be applied in a single coat while offering excellent abrasion resistance.

Greg Vaughn of Vaughn Engineering turned to Induron for a solution, and we delivered. Our solution was PermaClean 100 Ceramic Epoxy applied to 10.0 to 15.0 Mils DFT. This product offers absolute minimal undercutting, unrivaled Film Build (NSF approved up to 50 Mils DFT), ultra-low permeability and a non-ablative surface.

Because of PermaClean 100’s fast cure time (72 hours), Vaughn Engineering was able to proceed with rebuilding the aeration filters and returning Sardis Water Authority to service. In the end, Sardis Water Authority received much-needed maintenance on its water filtration system while maintaining its customers’ water demands.

To ensure AquaClean’s performance matches its user-friendly and good-looking finish, many important design traits are formulated into the coating system.

To ensure AquaClean’s performance matches its user-friendly and good-looking finish, many important design traits are formulated into the coating system.

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear. In its January 2016

In its January 2016

When it comes to potable water storage tanks, the Aqua Pennsylvania 10-million-gal Sproul Road ground storage tank in Philadelphia is about as big as they come. At 225 ft across and 40 ft high, this tank is critical to the Aqua Pennsylvania system. During the beginning of budget year 2014, the company determined that the massive tank needed to be recoated inside and out in order to be effectively maintained.

When it comes to potable water storage tanks, the Aqua Pennsylvania 10-million-gal Sproul Road ground storage tank in Philadelphia is about as big as they come. At 225 ft across and 40 ft high, this tank is critical to the Aqua Pennsylvania system. During the beginning of budget year 2014, the company determined that the massive tank needed to be recoated inside and out in order to be effectively maintained.