By: Rob Burckley, Induron Technical Sales and Service Representative

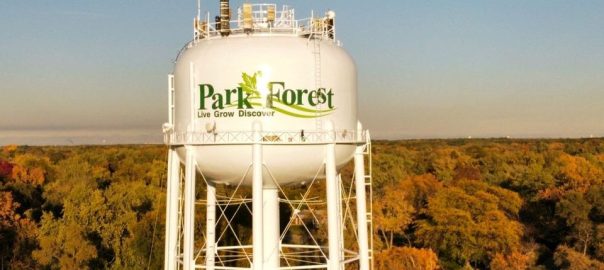

Water tanks often require rehabilitation due to various factors that affect their structural integrity and functionality over time. One key reason is corrosion, which can occur due to the exposure of tank materials to water and environmental elements, leading to deterioration of the tank’s surface and structural components. This corrosion weakens the tank’s ability to contain water safely and efficiently. This is often when a team steps in to rehabilitate the water tank. By undergoing rehabilitation, water tanks can be restored to optimal condition, ensuring reliable water storage, improved water quality, and extended lifespan of the infrastructure. A 500,000-gallon elevated water tank in Park Forest, Illinois was in need of rehabilitation for these exact reasons.

Water tanks often require rehabilitation due to various factors that affect their structural integrity and functionality over time. One key reason is corrosion, which can occur due to the exposure of tank materials to water and environmental elements, leading to deterioration of the tank’s surface and structural components. This corrosion weakens the tank’s ability to contain water safely and efficiently. This is often when a team steps in to rehabilitate the water tank. By undergoing rehabilitation, water tanks can be restored to optimal condition, ensuring reliable water storage, improved water quality, and extended lifespan of the infrastructure. A 500,000-gallon elevated water tank in Park Forest, Illinois was in need of rehabilitation for these exact reasons.

About the tank rehabilitation project

In this particular project, there were a few challenges to overcome, which involved:

- A narrow 50-day work window

- Working in close proximity to residential structures

- Installation of a new mixing system

- Foundation repairs

- Cathodic Protection system repairs

The Coatings Solution

Surface Preparation

Because the exterior of the tank was in relatively good condition, we were able to avoid abrasive air blasting, and achieve the proper cleanliness with a 10,000 psi pressure wash. This ensured all foreign dirt and debris, along with any old loosely-adherent paint, was removed completely. The interior was abrasive blast cleaned to an SSPC-SP10 near white metal substrate. This level of cleanliness is dictated by the immersion environment of the tank.

Exterior Coating System

Once surface preparation was complete, the following system was applied to the exterior of the tank:

- Spot Prime Coat: PE70

- Full Prime Coat: PE70

- Intermediate Coat: Indurethane 6600+

- Finish Coat: Indurethane 6600+

The exterior finish coat 6600+ was chosen because it provides long term color and gloss retention.

The exterior finish coat 6600+ was chosen because it provides long term color and gloss retention.

Interior System

Once surface preparation was complete, the following system was applied to the interior of the tank:

- Prime Coat: Indurazinc MC67

- Stripe Coat: PE70

- Intermediate: PE70

- Finish Coat: PE70

The interior tank photos show the tank in zinc primer and a PE70 stripe coat.

About the team

The team responsible for getting this job completed included representatives from Dixon Engineering, Semper Fi Industrial Coatings and Induron Protective Coatings. Dixon provided engineering services, including project assessment, specifications and inspection. Semper Fi Industrial Coatings was responsible for all surface preparation and coating application, while Induron manufactured the products to keep this asset in optimal working condition.