Joe Jones is a soft-spoken guy who doesn’t say a lot, but what he lacks in words, he makes up for in wisdom and loyalty to Induron. The guys in the plant simply refer to him as “the gray fox” – not necessarily cunning, but smarter than the average bear.

Joe Jones is a soft-spoken guy who doesn’t say a lot, but what he lacks in words, he makes up for in wisdom and loyalty to Induron. The guys in the plant simply refer to him as “the gray fox” – not necessarily cunning, but smarter than the average bear.

Joe has been working at Induron since 1983. His father, Noel Jones, worked at Induron for 38 years, so he’s known the place his entire life. In fact, Noel is part of the old Indurall days’ lore because of a tumble he took into a batch of red-oxide primer. Although he turned out to be uninjured, when he came up out of that batch of dark red primer, everyone in the place thought otherwise!

Joe is behind just about every paint product that Induron sells. He’s worked in all parts of our facility, from filling to maintenance to actually making our paint products. These days, Joe makes several batches every day. Most of these batches are different sizes, all of them use different raw materials located all over our facility (no one knows exactly how Joe keeps up with their locations!) and Joe knows how to use every single different piece of paint making equipment in our plant, from the old Ball Mills to the modern dyno-mill. In a nutshell and in his own words, “Joe makes the paint.”

Joe drives 60 miles to and from work everyday. In his own humble way Joe said, “I guess I’ve been through about seven or eight cars in my time here.” But he doesn’t mind the drive. “I like the people I work with. We have fun and joke with each other while we get our jobs done.”

Davies Hood, Induron president, is the third Hood man Joe has seen running Induron. “The Hoods are good guys,” he said.

The feeling is mutual for Davies. “Joe has been an important part of our team for three decades,” he said. “He does good work and we’re proud to have him as part of the Induron family. Continue reading Meet the Induron Family: Joe Jones →

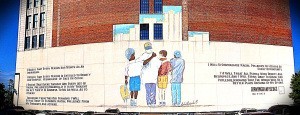

Not only do our products beautify and protect assets from corrosion, but our paints and coatings can also be used to create murals that convey meaningful messages and unify communities.

Not only do our products beautify and protect assets from corrosion, but our paints and coatings can also be used to create murals that convey meaningful messages and unify communities.