By: Russell Hicks, Induron Sales Representative

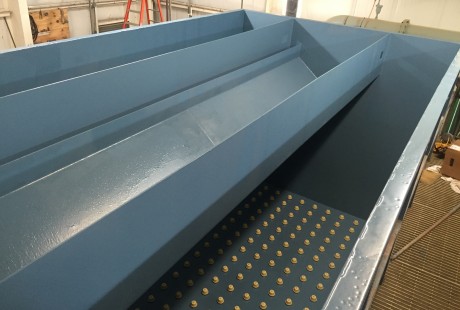

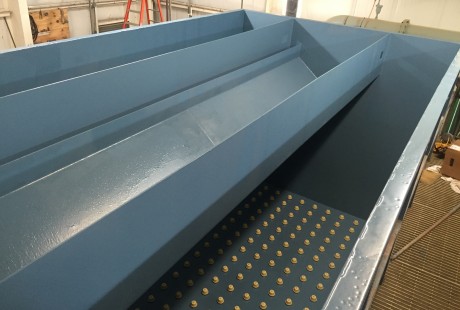

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

Sardis Water had two major problems. First, a new and larger clarifier needed to be built so that the two existing clarifiers could be converted into finish filters. Second, the water system needed a coating solution that could meet several demands. Sardis Water Authority needed the filter back in service quickly due to water usage demands. Additionally, the Sardis Water’s new coating system needed to be applied in a single coat while offering excellent abrasion resistance.

Greg Vaughn of Vaughn Engineering turned to Induron for a solution, and we delivered. Our solution was PermaClean 100 Ceramic Epoxy applied to 10.0 to 15.0 Mils DFT. This product offers absolute minimal undercutting, unrivaled Film Build (NSF approved up to 50 Mils DFT), ultra-low permeability and a non-ablative surface.

Because of PermaClean 100’s fast cure time (72 hours), Vaughn Engineering was able to proceed with rebuilding the aeration filters and returning Sardis Water Authority to service. In the end, Sardis Water Authority received much-needed maintenance on its water filtration system while maintaining its customers’ water demands.

Texarkana Water Utilities (TWU) decided its 400,000-gallon pedisphere water storage vessel located in Texarkana, Texas was due for some maintenance. TWU also realized they had a problem to address before beginning the project—the tank’s location. Because the tank was located in a residential area and surrounded by homes, TWU hoped to avoid disturbing the local neighborhood residents in any way. Continue reading Induron and Tankez Coatings Rehabilitate Texarkana’s Pedisphere Tank

Texarkana Water Utilities (TWU) decided its 400,000-gallon pedisphere water storage vessel located in Texarkana, Texas was due for some maintenance. TWU also realized they had a problem to address before beginning the project—the tank’s location. Because the tank was located in a residential area and surrounded by homes, TWU hoped to avoid disturbing the local neighborhood residents in any way. Continue reading Induron and Tankez Coatings Rehabilitate Texarkana’s Pedisphere Tank

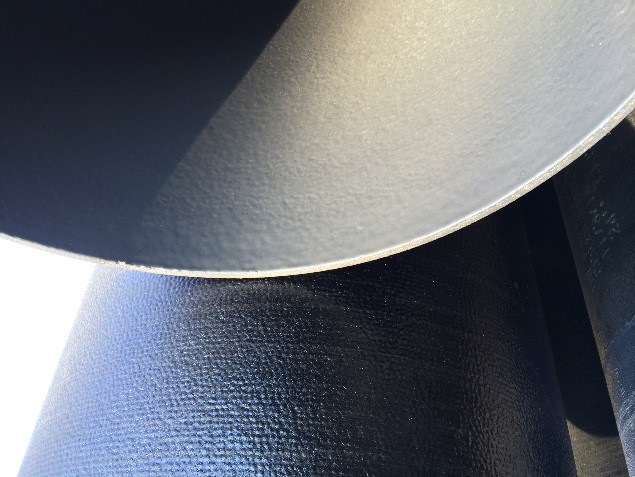

The “all-in-one” pipe lining solution is here. With Ceramapure PL-90 Ceramic Epoxy, Induron Protective Coatings brings decades of experience and technology to the pipe market. Founded in 1947, Induron is a privately-held industrial coatings manufacturer. Specializing in water and wastewater applications, Induron consistently produces unique coatings solutions that protect a variety of assets in infrastructure. From the industry standard ductile iron waste water pipe lining, Protecto 401, to its unique and proven line of ceramic epoxies, such as PermaClean 100 and Ceramasafe 90, Induron’s products protect nearly any immersion surface for water and wastewater treatment.

The “all-in-one” pipe lining solution is here. With Ceramapure PL-90 Ceramic Epoxy, Induron Protective Coatings brings decades of experience and technology to the pipe market. Founded in 1947, Induron is a privately-held industrial coatings manufacturer. Specializing in water and wastewater applications, Induron consistently produces unique coatings solutions that protect a variety of assets in infrastructure. From the industry standard ductile iron waste water pipe lining, Protecto 401, to its unique and proven line of ceramic epoxies, such as PermaClean 100 and Ceramasafe 90, Induron’s products protect nearly any immersion surface for water and wastewater treatment.  CEO of Induron Protective Coatings, Davies Hood, understands the importance of not only supplying the water and wastewater market with state-of-the-art technology, but also providing customers with exceptional support and service.

CEO of Induron Protective Coatings, Davies Hood, understands the importance of not only supplying the water and wastewater market with state-of-the-art technology, but also providing customers with exceptional support and service.  Recently, Induron was featured in CoatingsPro magazine’s

Recently, Induron was featured in CoatingsPro magazine’s  To ensure AquaClean’s performance matches its user-friendly and good-looking finish, many important design traits are formulated into the coating system.

To ensure AquaClean’s performance matches its user-friendly and good-looking finish, many important design traits are formulated into the coating system. Like most marketplaces, the industrial coating market becomes more and more competitive each day. Consequently, this competition cultivates an omnipresent sense of “We need to build a better mousetrap.” At Induron, our Research and Development Department is challenged with this exact task. With the help of our suppliers and partners, who consistently bring us the latest and greatest chemical technology, we are equipped with the necessary tools for innovation.

Like most marketplaces, the industrial coating market becomes more and more competitive each day. Consequently, this competition cultivates an omnipresent sense of “We need to build a better mousetrap.” At Induron, our Research and Development Department is challenged with this exact task. With the help of our suppliers and partners, who consistently bring us the latest and greatest chemical technology, we are equipped with the necessary tools for innovation.  Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

Recently, Induron provided materials to help Sardis Water Authority with a much-needed facelift. For nine years, the water and sewage utilities company located in Clayton, Oklahoma had two finish filters working double duty, and they were beginning to show signs of wear and tear.

When it comes to potable water storage tanks, the Aqua Pennsylvania 10-million-gal Sproul Road ground storage tank in Philadelphia is about as big as they come. At 225 ft across and 40 ft high, this tank is critical to the Aqua Pennsylvania system. During the beginning of budget year 2014, the company determined that the massive tank needed to be recoated inside and out in order to be effectively maintained.

When it comes to potable water storage tanks, the Aqua Pennsylvania 10-million-gal Sproul Road ground storage tank in Philadelphia is about as big as they come. At 225 ft across and 40 ft high, this tank is critical to the Aqua Pennsylvania system. During the beginning of budget year 2014, the company determined that the massive tank needed to be recoated inside and out in order to be effectively maintained.